Our Manufacturing Process

At Elegant Mark Engineering, every screw barrel and component is crafted with precision, durability, and performance in mind. Our state-of-the-art facility integrates advanced machinery, skilled manpower, and strict quality control to deliver products that meet global standards.

Raw Material Selection

We source only premium-grade alloy steels such as 38CrMoAlA, EN41B, H13, 0.2379, etc ensuring high wear resistance and toughness.

- Rigorous supplier evaluation.

- Material testing with chemical & mechanical certifications.

Forging & Rough Machining

To ensure strength and dimensional stability, billets undergo controlled forging before rough turning.

- Forging improves grain flow and durability.

- CNC turning for precise geometry.

Deep Hole Drilling & Gun Drilling

High-accuracy gun drilling machines are used for screw & barrel bores, ensuring concentricity and smooth finish.

- Bore tolerance within microns.

- Ready for nitriding or bimetallic lining.

Grinding & Honing

After drilling, the inner surfaces undergo precision grinding and honing to achieve the required smoothness and dimensional accuracy.

- Achieves surface finish up to Ra 0.3 – 0.5 µm

- Improves wear resistance and ensures uniform plastic flow

- Guarantees perfect alignment and concentricity

Heat Treatment & Hardening

Our components undergo advanced treatments for extended service life:

- Nitriding (900–1000 HV hardness)

- Vacuum heat treatment for dimensional accuracy

- Bimetallic alloy hardfacing for wear & corrosion resistance

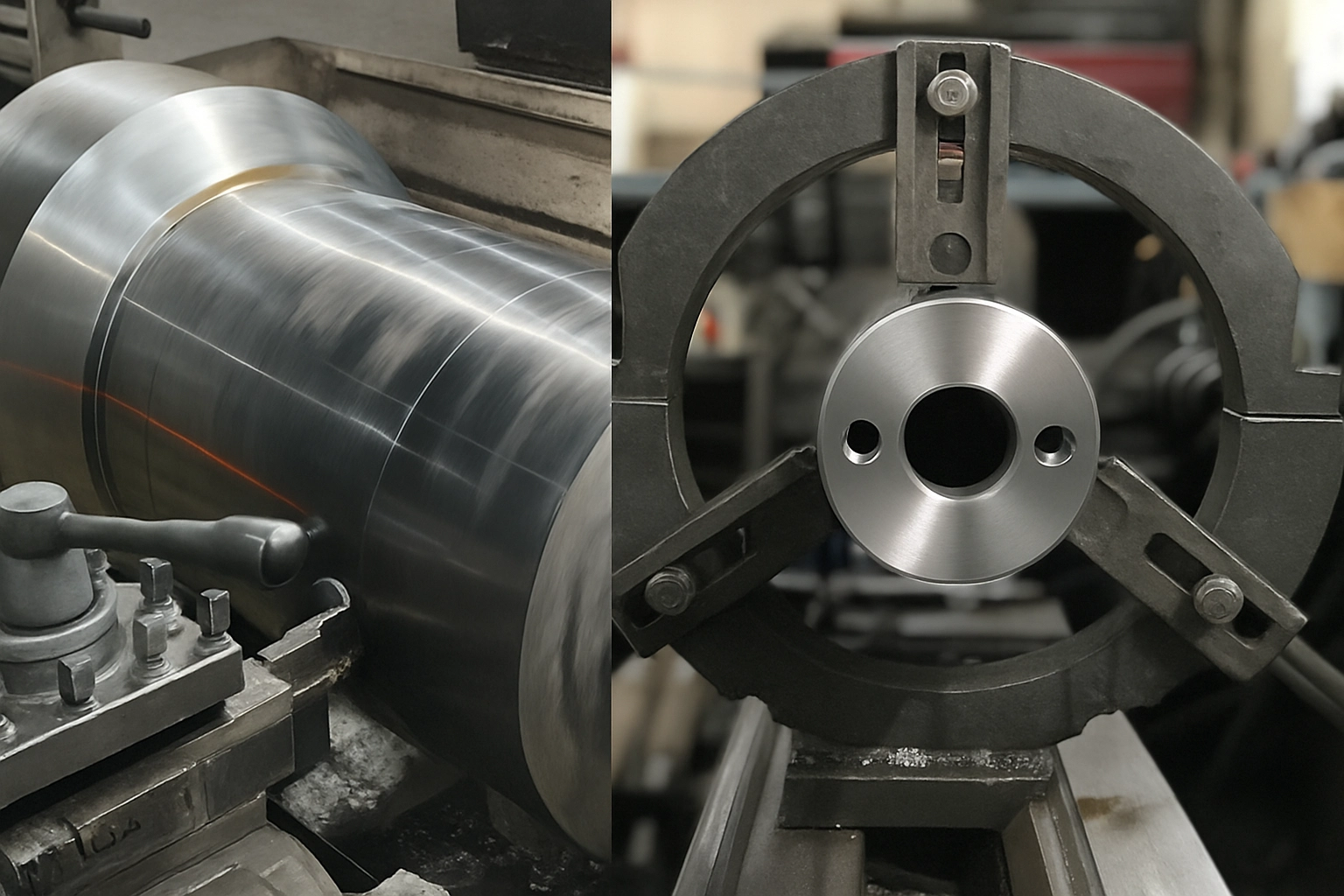

Precision Machining

CNC lathes, milling, and grinding machines ensure every screw flight, barrel groove, and sealing surface is manufactured to exact specifications.

- Flight depth accuracy ±0.01 mm

- Mirror finish for smooth plasticizing

Polishing Process

After machining, screws undergo manual and machine polishing to refine flight edges and improve melt flow characteristics.

- Removes micro-burrs and machining marks

- Achieves high-gloss finish up to Ra 0.2 – 0.4 µm for reduced friction

- Enhances wear resistance and plasticizing efficiency

Surface Coatings & Cladding

Depending on application, we provide specialized coatings:

- Tungsten Carbide, Nickel Alloy, PTA Welding

- Hard Chrome Plating, PVD & other wear-resistant layers

Quality Inspection & Testing

Every product undergoes 100% dimensional and hardness testing.

- Ultrasonic & magnetic particle inspection

- Hardness test (Rockwell & Vickers)

- Trial assembly for perfect fitting

Final Assembly & Dispatch

Finished screw barrels, plungers, and components are assembled, packed, and dispatched with complete traceability.

- Inspection reports & test certificates provided

- Export-compliant packaging for global delivery